December 10, 2021 - 6 minute read

“What a difference a year makes!”

Lots of us say this, but oh boy has it applied over the last couple of years! Ignoring the obvious things going on in the world, which often seem to be an amalgamation of constant doom and covid gloom, there have been some real shifts of positivity in the heating industry.

So, before we leave 2021 (its actually ‘Christmas Jumper Day’ today and yes I'm wearing one writing this) let's head back to 2020 and the work that myself and a few others (Kim ‘Kimbo’ Betty, Jo Alsop, Rob Berridge and Paul Hull) were doing to promote the reduction of gas boiler energy wastage earlier on in this year.

Unbeknown to us, one person amongst the installers attending one of Kimbo’s Heating Academy Northampton training courses at the time, was listening to him harping on about the #energywastage crisis that we were facing with condensing gas boilers (I wrote about this in March 2020) and technically what installers could do to mitigate it. In July 2020 a #killakilowatt campaign was started on Twitter off the back of the information taken from Kimbo's course.

Although there are several people who have been promoting modulation controls, Priority Domestic Hot Water (PDHW) and lower flow temperature systems for many years, sometimes it does take some time to understand why, and a light bulb moment (with the right people at the right time), then leads to people in the right circles running with the same message. Before you know it, your ‘seed’ gathers pace, and like the acorn over many years, a mighty oak of the idea grows. I will always be grateful that Micheal Walsh was on Kimbo’s course that day and for him that lightbulb moment occurred too.

Since this point, I've seen lots of installers and companies jump on the 'condensing boilers actually condensing' bandwagon, promoting lowering boiler flow temperatures and literally telling people to turn the flow temperature dial down on your condensing boiler, as a quick and effective 'fix'. Great news! But my question is, at what point does this good advice become bad advice?

Why does reducing flow temperatures on condensing boilers make such a big difference?

It's all about recovering as much energy as you can from the combustion process. The lower the heating flow temperature, the lower the heat exchanger temperature and the more chance you have of capturing the energy contained within the water vapour in the flue gasses. I’ve already written about how this works in ‘Why Your Condensing Boiler Isn’t Efficient’ if you would like to understand more about the subject.

If turning down the flow temperature, saves energy and money, how can it also be bad advice too?

The heating installers I train and work with daily are fully qualified to give technical advice to their customers. Sadly, heating installers have been massively undervalued for way too long. Consumer advice groups, forums and energy suppliers should really stick to what they are good at, which is giving good support to their customers, networks and any advice they do give to consumers, should be within the safe technical limits of their own knowledge or with reference to the official documentation.

Why am I saying this? Well, recently I caught wind of the ‘Octopus Winter Workout’ on Octopus Energy’s blog page ‘helping’ their customers get winter-ready. One piece of advice Pete Miller, Octopus Energy’s Head of Customer Experience promoted was...

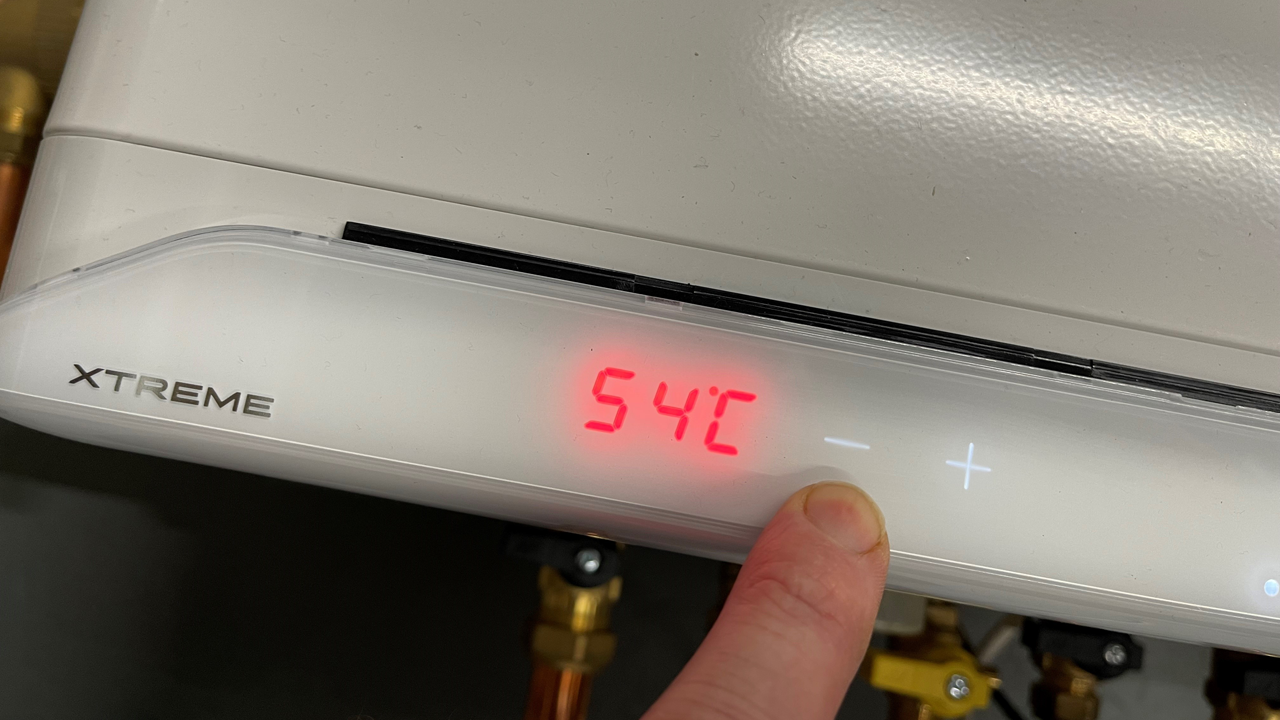

"If you have a boiler and a hot water cylinder, we recommend setting the flow temperature on your boiler to 55c for heating and hot water, and setting your hot water cylinder to 55c also (you’ll usually find the control for your cylinder ⅓ of the way up the tank.)”.

After a few people advised Octopus Energy of this error on Twitter, they have updated the information to storing water at 60°C, although (at the time of me writing this) they are still stating a 60C boiler flow temperature would be sufficient (which sadly it won't) and I would recommend a minimum flow temperature of 70°C, to allow for any temperature drops between the boiler and the cylinder, thus allowing the cylinder to actually satisfy its thermostat setpoint.

To me, this just shows a clear lack of knowledge some companies trying to move into the heating industry have, even if its with the best intention. Sadly, I have seen many times where big companies jump on the back of others hard work, but the translation gets lost along the way due to a lack of understanding of the subject they are engaging with. Sometimes worse than this, all the information is plagiarised from another blog and the right people are not credited for their hard work and previous efforts.

Should you reduce your flow temperature with a heating system with a hot water cylinder then?

Combi boilers are very different from boilers with cylinders, and if you turn down the temperature of your combi boiler too much, the worst that may happen is your home will be too cold.

Boilers with hot water cylinders however, can be a haven for Legionella bacteria if the correct temperature of stored hot water is not maintained. HSE guidance on hot water storage clearly states within the first paragraph “hot water should be stored at least at 60°C”. So why would anyone dream of releasing advice about hot water storage that contravenes HSE’s guidance?

I asked Jo Alsop at The Heating Hub what her thoughts were, and she commented...

“There is no blanket, one-size-fits-all, answer for this. The course of action needed to lower the flow temperature for heating and maintain a safe hot water cylinder temperature will depend on the capability of the boiler and heating controls. In most cases we find a solution or a work-around, but it is an intervention paired with an installer who actually understands these principles. That alone is a needle in a haystack.”

My best advice is to get a qualified and competent installer to assess your system and decide if this is possible for you. If you currently have an S or Y Plan system, your boiler (manufacturer dependant of course) might already have the capability to be converted to a Priority Domestic Hot Water system, which can then run safely at lower temperatures when doing the space heating, but still recover the cylinder to the correct temperature of 60°C as defined by the HSE. For instance, if you have an Intergas boiler on an S or Y Plan currently, this can be easily converted/upgraded to PDHW!

As a regular consumer of products and services myself, there is some really good energy saving advice out there. I have been a massive supporter of Octopus Energy over the years, and they have led the way with how I think about ‘smart electricity’. But please, please, please, do not lower the flow temperatures on boilers with cylinders, without fully consulting a competent heating installer first!

Author - Richard Burrows, Director, The INTERGAS Shop

The INTERGAS Shop specialise in Intergas modulation boilers and OpenTherm enabled control systems to maximise energy efficiency and comfort. We also jointly run a Facebook group to help heating installers understand OpenTherm controls and advanced heating system design. Find our group here - https://www.facebook.com/groups/thedeltatforum

If you have any questions or comments, please contact sales@theintergasshop.co.uk and our expert staff can help you.