March 11, 2020 - 5 minute read

During my research into what people wanted to know about OpenTherm, the same recurring question kept creeping up over the many forums and search engines I use...

"Is OpenTherm really worth it?"

I found however, the online articles about OpenTherm in reply to this question, were written by people who are not in the heating industry and their information was based on basic manufacturers information and data.

My own experience of OpenTherm controls and boilers is 100% first hand, with many years of industry application and product testing. I also enjoy training heating installers on modulation controls using OpenTherm, so I'm well positioned to give the correct information throughout this article.

But before I can answer the main question, there are some points to correctly understand.

What is OpenTherm?

OpenTherm is simply a way for heating controls to communicate their data to the central heating appliance and vice versa. Traditionally, OpenTherm has been limited to modulation gas boilers, but in theory any type of heating technology could use OpenTherm (oil boilers and heat pumps for example).

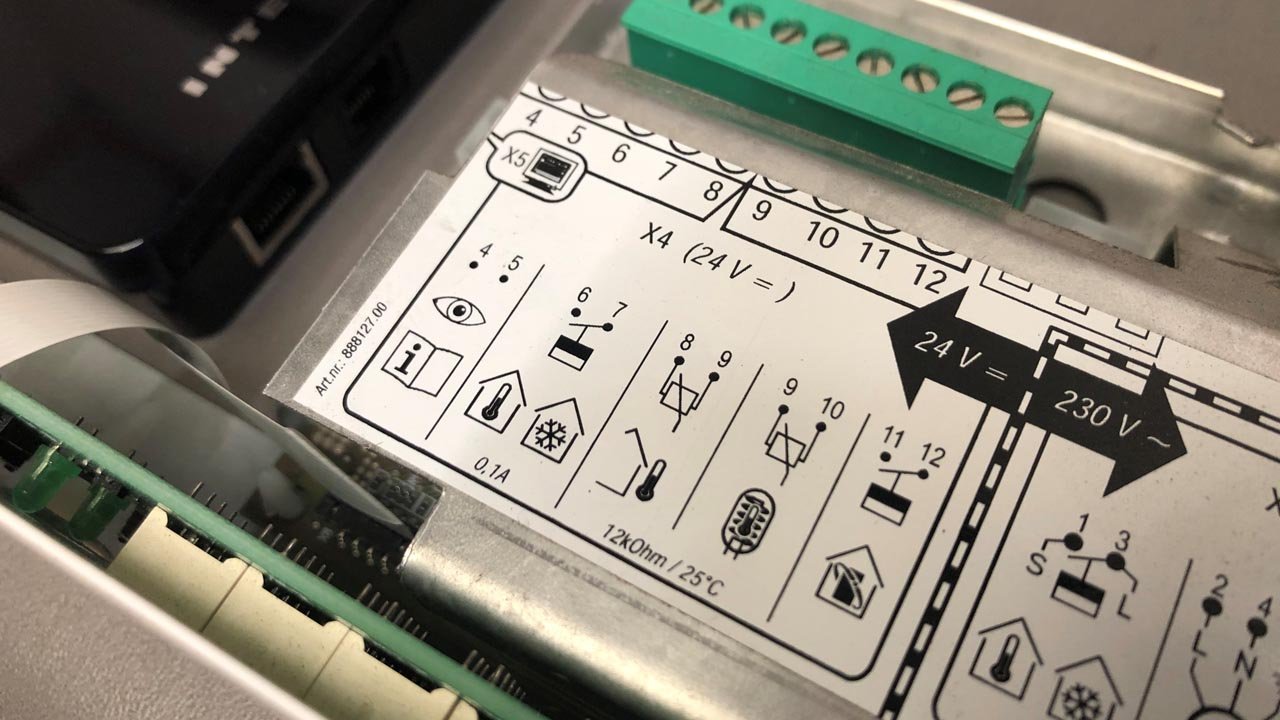

OpenTherm communicates using a wired connection, with a digital language made from voltage and current that both the thermostat and the boiler can understand.

OpenTherm uses commands called 'Data ID's' to understand and adjust parameters. One Data ID might contain the outside air temperature and another Data ID might contain the temperature the thermostat wants the boiler to run at for instance. By communicating these Data ID's between the thermostat and the heating appliance, the whole system understands what is currently happening and what needs to happen in the future.

What's the difference between OpenTherm enabled and normal heating controls?

Heating controls in the UK and Europe are classified into different 'groups' based on their capabilities and this is called 'ErP Classification'. This control classification ranges between Class 1 to Class 8 and the individual classes define their capability.

OpenTherm enabled controls have the ability to communicate with the boiler and modulate the boilers output. Therefore, OpenTherm enabled controls can be ErP Class 5, 6 or 8. Heating controls that cannot control the boiler intuitively are defined by ErP Class 1 (Hive is an ErP Class 1 thermostat and uses basic on/off control) or ErP Class 4 (Honeywell Home T4 uses TPI control which is a form of algorithmic on/off control).

ErP Control Classifications are directly linked to the energy efficiency capabilities of the controls. Therefore, ErP Class 1 & 4 thermostats have been deemed less efficient when used with a modulation boiler than if ErP Class 5, 6 & 8 thermostats are used.

So are OpenTherm enabled controls 'smart controls'?

In a nutshell - yes, but not necessarily in the true definition of the word.

Most people understand a 'smart thermostat' to be a thermostat that can be controlled from a smartphone, tablet or smart home device (like a smart speaker).

However this is not what a smart control is defined as.

Back in April 2018, the UK Government attempted to improve the energy efficiency of the boilers being fitted in UK domestic properties by introducing a new standard called 'Boiler Plus'. This new standard defines a 'smart control' as one that can intelligently start the heating system at the right time to reach the user defined temperature set point (what we call 'Optimum Start') and a thermostat that can be programmed individually over 7 days. This new definition was not really a great improvement of the standard, based on the fact we were selling OpenTherm enabled controls capable of much more than this, prior to the introduction of Boiler Plus.

My personal view is that the best type of 'smart control' is an internet connected thermostat (with optimum start and stop), which also has the ability to modulate the boilers output.

If OpenTherm enabled controls are better, why are they not used more?

This is a really good question. But I have a few ideas.

So firstly, you have to ask why an open communication standard like OpenTherm was created? The simple answer is 'innovation'. By having an open communication standard, control manufacturers could create products that (in theory) could work with any heating appliance using the same open communication standard. If you look at the Nest Learning Thermostat for instance, this has been a highly innovative product. When Nest launched the 3rd Generation of the learning thermostat, it was created to be OpenTherm enabled and works with the Intergas OpenTherm enabled boilers I've fitted it to.

Boiler manufacturers with closed digital connections, such as Worcester's BB/EMS or Valliant's e-BUS can only be switched on and off with a Nest thermostat (using the boilers 230v connection), instead of being dynamically controlled in an efficient way with OpenTherm. The only way to run these modulation boilers efficiently, is with the boiler manufacturers own controls. However, this is at the cost of innovation and choice. If a customer wants a particular thermostat, it really shouldn't affect the boilers efficiency because of this.

Secondly, OpenTherm is licensed by the OpenTherm Association. To become an OpenTherm Association Member, you have to pay for annual membership and this is costly, which could hold smaller thermostat manufacturers back. Unfortunately, I find their website hard to navigate and the products members create aren't always independently tested for compatibility. When there are compatibility issues, manufacturers are not held to account for any shortcomings. 'Unregulated' is an understatement and this is shown on a regular basis, where I see installers struggling with OpenTherm thermostats, on so called OpenTherm enabled boilers. Sadly it is hard to write about the OpenTherm Association without being negative, but they have made things harder than they should be.

Thirdly, some manufacturers have attempted to make their own OpenTherm enabled controls, the only controls that will work with their boilers. I can name 3 boiler manufacturers that have made OpenTherm controls harder than they should be to fit. The Baxi 600 Series boiler is one of them. This boiler needs the controls to have the Domestic Hot Water (DHW) Data ID for the controls to be compatible with the boiler. The problem is, the OpenTherm Protocol Specification doesn't require OpenTherm enabled controls to have this Data ID. This has resulted in many frustrated installers and quite rightly so. Baxi's own OpenTherm enabled controls have this Data ID and this is a way of preventing installers using other 3rd party controls on their boiler that don't have this Data ID.

So is OpenTherm worth it?

Yes, hand on heart, the right OpenTherm enabled control used with the right Opentherm enabled boiler is 100% worth it. The intelligence that can be utilised by controls reading the boilers data, is far more advanced than a control system with no feedback of the boiler or its surroundings.

Are OpenTherm enabled controls trouble free? Sadly I have to be honest and say no. Right now, OpenTherm enabled controls are being dragged through the mud because of the lack of standardisation and testing with some OpenTherm boilers.

However, like I always say... Get the right expert advice, the combination correct and simply sit back and watch your comfort levels increase and energy bills reduce.

When this happens, it really is the mark of an advanced and intuitive heating system!

Author - Richard Burrows, Director, The INTERGAS Shop

The INTERGAS Shop specialise in Intergas modulation boilers and OpenTherm enabled control systems to maximise energy efficiency and comfort. We also jointly run a Facebook group to help installers understand OpenTherm controls and advanced heating system design. Find our group here - https://www.facebook.com/groups/thedeltatforum

If you have any questions or comments, please contact sales@theintergasshop.co.uk and our expert staff can help you.